Here at GeekDad, we tend to be early adopters. It’s kind of our thing, but just as some of us are quicker to pick up the latest gaming console than the hot new entry in the smart home marketplace or the very latest in automotive technologies, we each have areas where we, for one reason or another, lag behind. For me, that’s been 3D printing.

I’ll be honest here; while other GeekDads like Anton and Rory have been showcasing new printer tech and amazing builds for ages, I have long struggled to understand exactly what 3D printing is and why I’d even want to do it.

Recently, though, I had a breakthrough. After reading reviews, tips, and project ideas on GeekDad for years—and finally replacing the phrase “3D printing” in my head with the more precise “additive manufacturing“—I got it. It’s simply the art (and science!) of using CAD-style files to print three-dimensional objects by extruding layer upon layer of adhesive material.

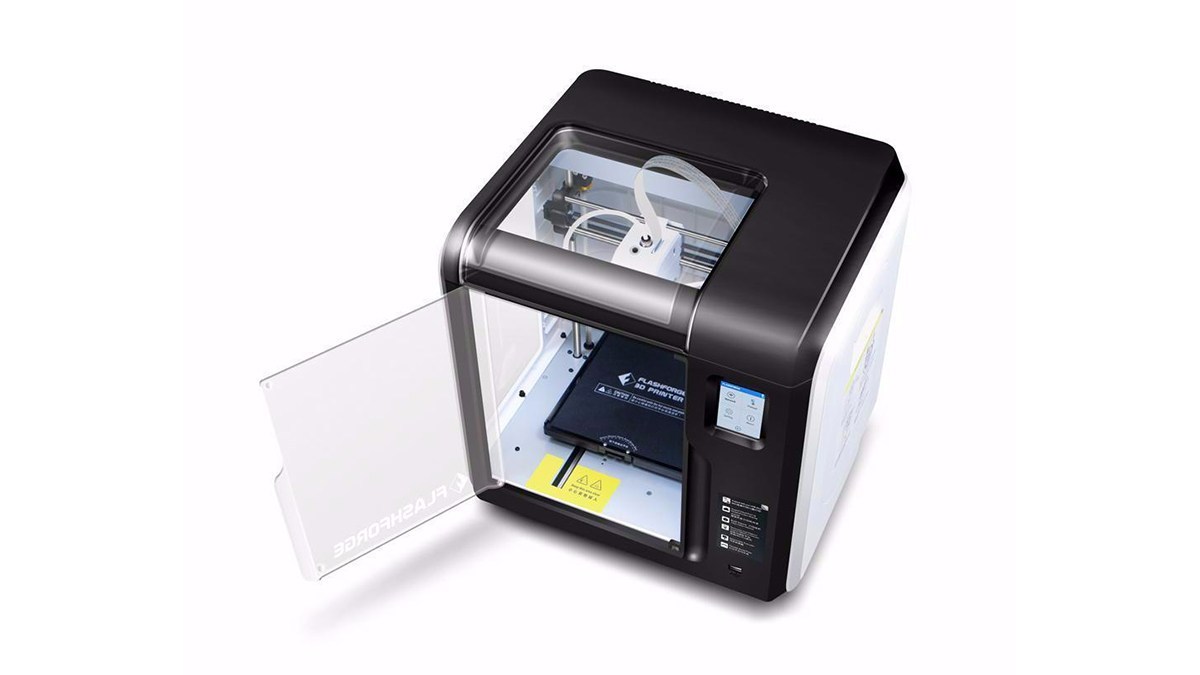

When the offer of a review unit was recently made by FlashForge USA, I did a little digging. The printer in question, their Adventurer 3, was a sleek, non-threatening device, a little smaller than your college dorm fridge—a far cry from the exposed filament spools and finicky adjustable beds of early 3D printing.

I followed up, and within a few days, I was hauling in a sizable cardboard box along with my regular FedEx haul. Over the next couple of weeks (and after a few minor hiccups), I found the Adventurer 3 to be a perfect fit for the burgeoning crafter. More importantly, I discovered that even I could learn to 3D print.

What’s in the Box?

Assuaging any lingering anxiety, the Adventurer 3 arrived preassembled. Along with the printer itself, the package also included a .3 kg spool of 1.75mm diameter red PLA filament, the requisite power cable, a quick-start guide and service card (more on those later), a small screwdriver and allen wrench, an unclogging tool, and some grease to keep the whole thing running smoothly. (Don’t fret; the printer comes pre-lubricated.)

The guidebook even came complete with unpacking instructions. Admittedly, that’s not something most users may need, but it was a nice addition.

Setup

Setup was a relative breeze, and I was up and printing within 40-minutes or so. After removing the packing materials (taking care to set aside my filament and mini toolkit) and hoisting out the printer itself, it was just a matter of finding an appropriate location to set it up. Thankfully, due to its small footprint—the Adventurer 3 is roughly a 16-inch cube—it fits easily even under most workroom or kitchen cabinets.

After powering up the printer, I was greeted with a friendly, chirpy tone and was immediately drawn to its 2.8-inch, color touchscreen. I navigated to Filament–>Load, removed the cover and loaded the spool clockwise onto the holder, pushed the free end into the intake, and waited for the extruder to preheat. Once the red filament became visible at the extruder tip, I was good to go.

I then proceeded to print my first model, a simple 20mm box already preloaded in the system memory, as directed in my quick start guide. It wasn’t until a few minutes in, upon discovering that my box was more of a glob of filament stuck to the extruder nozzle, that I realized something was wrong.

Unfortunately, it turns out that one very important step was missing from my quick-start guide: calibration. Thankfully, a YouTube video on the FlashForge USA channel helped me tweak the Z-axis using nothing more than a simple piece of paper.

With that done, it was off to the races. I was now the proud owner of a small, red box.

Networking

With this preloaded project printed, it was time to move onto bigger and better things. The only question was how. As with most current-gen technology, the Adventurer 3 supports Wi-Fi. Unfortunately, the machine kept telling me that my network was unstable. Luckily, there’s also LAN support, and I happen to keep a Wi-Fi expander that supports LAN-out around for just such emergencies.

For the more adventurous among us, you can set the Adventurer 3 itself up as a wireless printing hotspot. The most impressive option, however, is via the FlashCloud service. Not only does FlashCloud allow for remote 3D printing, it also gives users file storage, an integrated model library, and even lets you monitor your prints using the Adventurer’s built-in 2MP camera.

Honestly, though, I tend to use the conveniently located front USB port. I just dump my print files on a flash drive, plug it in, and navigate to the job I want using the touchscreen. It’s certainly not as impressive as a cloud-based service, but it also means I don’t have to leave my printer on all the time in case the urge to craft happens to hit.

Software

It’s important to note that, while most of the project files you’ll find at community portals like Thingiverse and Shapeways are STL files, you’ll need to convert those to the GX format before printing. This is done using the companion FlashPrint software. Now, this too was omitted from the quick-start guide, but it was easy enough to find on the Download page of the FlashForge USA site, and there are a number of good tutorial videos available via YouTube.

FlashPrint has a pretty simple, stripped-down interface, which makes it intuitive but also a little clunky. Loading, viewing, rotating, and even slicing an object is very easy using the onscreen toolbars, but toggling on and off the secondary menus and moving from one function to the other can sometimes feel tedious.

That said, FlashPrint is novice-friendly, in that its great about warning you when a model isn’t accounting for the height of the build platform. It also makes adding supports, rafts, and brims a breeze—though, if you’re anything like me, you’ll have to look up what those even are during your first few projects.

There’s even an Auto Supports option that searches the item for structural weak points and automatically reinforces them. Although, I am beginning to suspect that this function can be a bit overambitious. Regardless, once your project has been sliced, supported, and rafted to your liking, just click the print button, choose your material and resolution, and you’re good to go whether you’re sending directly to your printer or exporting to a removable drive.

Support

Speaking of support in a more traditional sense, I did have an opportunity to contact FlashForge USA customer service. (That’s sort of the best-case/worst-case scenario when it comes to reviewing new tech. On the one hand, you just want stuff to work, while on the other, you do want to get a feel for how customers are treated in times of trouble.)

The FlashForge USA Contact page offers phone support from 9AM-5PM Pacific, but since I’m on the east coast (and hate making phone calls), I instead opted to email them.

You see, while the available YouTube video gave me a great overview of unchoking a clogged extruder nozzle, mine had a sizable chunk on unmelted filament poking out of the top. I figured before I started manhandling my printer, I’d likely better consult the professionals.

To my delight, I received a follow-up email from an actual person within 4 hours of my initial request. Rather than just spit out some pre-prepared how-tos, I was talked through my specific problem by someone who actually knew how my printer worked. It was refreshing, to say the least.

Issues and Limitations

As you can probably tell, I really like my Adventurer 3, but nothing is ever perfect. While my knocks against the product are relatively minor, they’re still things to consider.

First and foremost, and as I’ve already mentioned, the pack-in documentation is lacking. While there’s an expanded 40-page user guide available online from FlashForge USA, the paper quick-start guide (in both Chinese and English) is a meager 16 pages. There’s also no option to register your product online. Instead, you’re expected to mail in the completed service card, even though the mailing address for FlashForge USA isn’t included—just that of the original corporate branch in Jinhua. It’s also probably worth noting that the registration email for the FlashCloud service was in Chinese as well, but finding the confirmation code to activate my account was easy enough.

The Adventurer 3 boasts a sliding platform with a heated removable build plate. Releasing the plate is easy—it’s just a matter of pinching it between your thumb and forefinger—and the heat dissipates quickly enough upon removal. Still, even with all these amenities, there’s a distinct learning curve for unsticking your builds. You’re also limited to 150mm (just under 6 inches) x 150mm x 150mm of build space per print. This is fine for my purposes, but also worth a mention.

Lastly, and this one is what I consider my only real caveat, there’s the issue of filament. Because of the Adventurer’s enclosed filament area and auto-feed function, you’re basically looking at a proprietary system. FlashForge PLA seems to be pretty standard 1.75mm filament, but it’s sold on smaller .5kg spools to fit within the printer’s tiny footprint. Said spools also use 20mm spool hub hole, rather than the more standard 2(ish) inches. This means you’ll either need to pay a premium for FlashForge product, re-spool new filament on your existing mini-spool… or just 3D print an external spool holder.

The Results

I’m going to give it to you straight, folks; pretty much all of the 3D printing projects I’ve done over the past two weeks have been related to tabletop roleplaying. (Said the guy with the big ol’ D20 tattoo to absolutely no one’s surprise.)

There is an absolute wealth of free gaming miniature files—not to mention things like storage boxes, dice towers, and the like—out there just waiting for you to find them. While the printer’s .4mm extrusion nozzle doesn’t exactly capture the finer facial details, it’s been more than adequate for cranking out minis and other accessories.

At the standard resolution (.27mm for the first layer, .18 for the rest), I was happy with the results. Even when there was some stringing present, I knocked it out quickly with a micro cutter and needle file.

Recommendation

When I’m reviewing a new home gadget, my ultimate focus is generally on whether or not it noticeably improves my quality of life. Does it save me time, money, or effort? Does it help keep my home, and thus my life, cleaner or safer or more organized?

With the FlashForge USA Adventurer 3, that metric doesn’t exactly track. A 3D printer, even an affordable model like this, is still more of a luxury item. It’s not a vacuum or a security camera; it’s not the kind of thing you’d likely end up buying out of need.

That said, I can confidently state that the Adventurer 3 has certainly made me more creative. Moreover, it helped reduce the intimidation factor inherent in 3D printing. I made things, I had fun, and I think you will too.

At $449, you get a reliable 3D printer with great customer support that doesn’t break the bank or your eardrums. (I measured it at a modest 45dB with the occasional bump into the mid-50s.) This makes it perfect for classroom or home hobbyist use… and, if I’m any indicator, an amazing match for tabletop roleplaying enthusiasts.

Review materials provided by FlashForge USA.

Nice Post… Thanks for shearing this ..

it’s very informative for me…

We are also here to solve all kind of complications regards Brother Printer.

If your printer lacks any kind of technical support, just dial Brother Wireless Printer Customer Service Number toll-free+1-855-516-8295. We will instantly resolve your issue and provide the best way solution by the professional experts.

I chose to get an Adventurer 3 also because of the (generally) great reviews.They were well deserved. I’ve cranked out a dozen max size vases and a host of other trinkets in the last two months. I found that using Polar Cloud was the easiest way to set up a new build since it automatically converts the ubiquitous .stl files into the .gx3 files that the printer requires. Many of the other issues you mention in your review appear to have been eradicated though the learning curve is still a bit steep for a newbie to encounter. All in all, I marvel at it’s precision and am generally mesmerized watching it perform it’s twitchy dance. I urge all owners to crank out the series of articulated dogs, cats and elephants. Great gifts for the children in the family.