I haven’t used my 3D printers much since February, so most of my filament has been sitting on the shelf since. This has not been an issue in recent years as this part of Texas is reasonably dry, and unusually so the last 5 years. This winter and spring, however, have conspired to teach me a lesson about the proper treatment and storage of PLA printer filament. Since the rains started, my open spools of hydrophilic PLA have been sucking up humidity. This change has greatly affected the quality and success of my recent print jobs.

The first (and probably most critical) problem is the filament swells slightly. This swelling not only increases the diameter of the filament, it weakens the surface. Both of these factors conspire to increase friction in the extruder and print head, and cause filament jams. The other issue is that small pockets of moisture can violently flash to steam in the nozzle causing warts and imperfections in the print.

After emailing with Push Plastic about the filament, they offered to send some fresh samples so I could compare them with mine. Tests with the fresh filament worked great with no change to the printer, so that ruled out any mechanical problems with the extruder. I decided to attempt to dry out the water logged PLA and see if I could recover it. Some time with Google showed that there two options. The slowest involved sealing the filament in a bag or plastic container with some desiccant and waiting. The other entailed baking the filament in the oven at a low temp to dehydrate it. In the end I picked both methods, but chose to drive out the moisture in the oven first, then store it in sealed containers with desiccant.

I Googled a few success stories, and a couple disasters, on baking filament. The key was to stay well below the melting point of both the filament and the spool. I chose to start cool and bump up slowly to see what happens. In the end I baked the filament for about 2 hours at roughly 180F with the oven door cracked open a little. If you attempt this I would caution that you recognize the difference between 180 Fahrenheit and 180 Celsius. The latter is close to the temperature of the printhead and will result in a puddle of filament in your oven. There was one great photo of such a disaster on one of the forum posts I’d read, though he only went to 100C and had problems. I never let mine top 80C and kept it closer to 70.

After 2 hours in the oven I put one spool on the printer for a test. The rest went into a large, airtight Rubber Maid container with some desiccant. The oven dried filament returned to its original size, color, and texture, and it printed as well as the fresh samples that Push Plastic sent. Now when I’m done printing I stick the filament back in the airtight container instead of leaving it sitting on the printer.

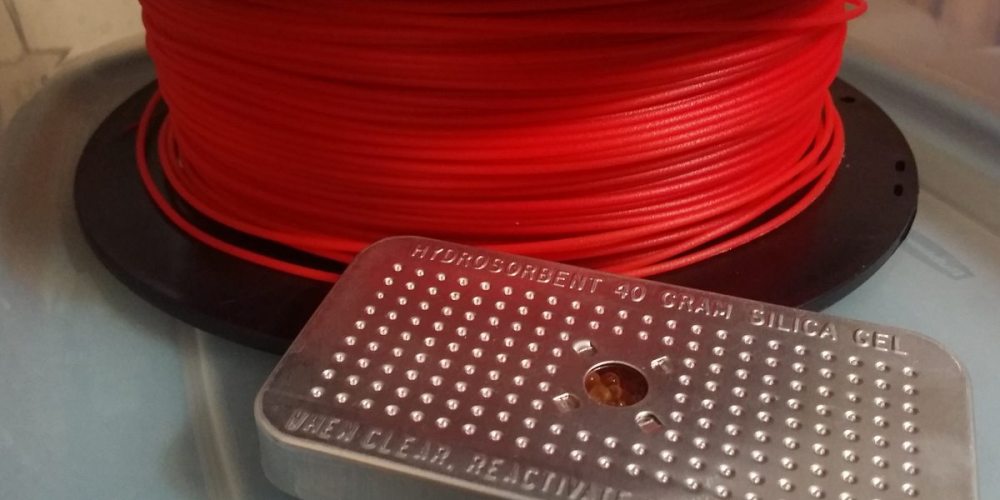

If you’re looking for some desiccant, I picked up these reusable Hydrosorbent canisters on Amazon for cheap. You can also get bulk color changing desiccant for less if you don’t mind the silica pebbles rolling around in your container. The cans I bought can be recharged in the oven at 300F for 3 hours.

Have you considered Filadry? Works for me

Thanks for the printing tips! This is sure to come in handy for me soon. Great advice.

Never had any issues (or i think i do not)with humidity. What does humid filament does to a print?

Hi Anton Olsen, thanks for posting. 3D printing gives you the opportunity to transform your imagination into reality. You can create new objects and prototype to invent new technology. It can be effectively used in various fields like medical, fashion and design etc. Researchers have been looking into 3D printing food and human organs. And engineers have already 3D printed many prosthetic limbs, bones, beaks, tails, etc. to help humans and wildlife. A few months ago, I got the services from “Iannone 3D” who provides best FDM 3D Printing Services (ABS, Nylon, PC, Ultem, etc.) in the New Jersey area.

Thanks for this information. I’m in Austin so I guess we are in the same boat.