As the owner of two home-built 3D printers, I can attest that they are quite finicky. Now that I have them calibrated I can get consistent prints with known filaments. Unfortunately each and every filament brand, and color, behaves differently. The ideal temperature and sometimes speed of the print head can vary greatly between colors and finish. More often than not the difference is only a few degrees, but those few degrees can mean the difference between a great or failed print job.

The Robox 3D printer is an attempt to reduce the finicky nature of the 3D printing process with a number of innovations. Some of these I’ve seen before, but Robox may be one of the first to compile them, and more, into one reasonably priced plug-and-print machine.

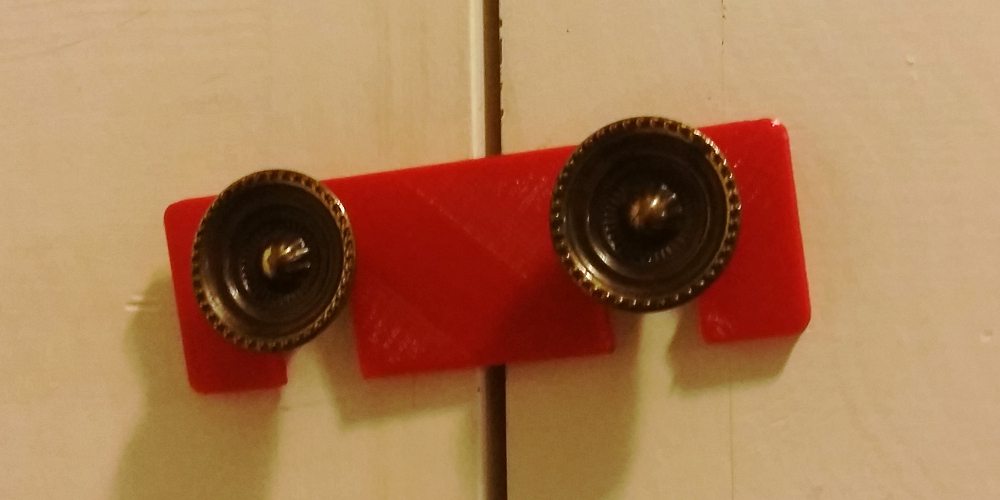

Probably the most interesting change for Robox is their print head. To speed up print jobs, the standard print head feeds two nozzles with one filament. One of the nozzles is smaller than the other to allow for detailed outer shells while using the larger one for infill. Robox claims that this alone can increase print speed by up to 300%. They have added needle valves to control the flow out of each nozzle. These valves can be used to virtually eliminate stringing, a common problem with 3D printers when the nozzle oozes a string of plastic when it shouldn’t.

The stepper motors that Robox chose for the printer are all oversized. I don’t think it’s critical for the x,y, or z axis, but it may come in handy if a heavier print head becomes available. The extra torque on the extruder though can definitely help push the filament through the nozzle at lower temperatures. This would make bridging gaps easier, as well as help control the stringing.

To take the guesswork out of the filament settings, Robox uses a coded spool and their own AutoMaker software. The printer detects the spool installed and automatically adjusts all of the settings accordingly. At first glance I thought the spools would be proprietary and closed, but it appears that Robox supports winding your own filament on their spools and reprogramming the eeprom with its settings. Robox branded filament, at about $40 USD for 600 grams, is about more than twice what I pay for PLA and ABS from Push Plastic. For anyone who doesn’t want to dial in the parameters of each new filament this may be a premium worth paying.

I haven’t taken a close look at their software, AutoMaker, but the screenshots I saw look like it is adequate.

In an attempt to make 3D printing more accessible for families, Robox is rethinking the design in an attempt to achieve something close to a plug and print design. I don’t think the open source slicing and control programs are terrible, but getting them to run on some systems can be a challenge. AutoMaker should solve that issue, and they do provide versions for Mac, Linux and PC.

Weighing in at about $1400-1500 in the US, the Robox isn’t the cheapest turnkey printer, but if their claims hold up it would be one of the easiest to setup and use. I’d be interested in taking one for a test drive, but for the price I think I’ll stick with my DIY models.

You can find out more about the Robox at their site, or read through their successful and delivered Kickstarter to see a glimpse into the design process. More information is also available on their forum.

Google’s hilarious. They put an ad covering the page, withe the option to close the ad, and provide feedback.

Option 1 is to report that the ad covers the page, at which point Google replaces the ad with a blurb that says, “Thanks for the feedback!”… still covering the page.

Go home Google. You’re drunk.