I’m one of those people who is obsessed with technology and gadgets, so it may be somewhat of a surprise that, up until a month ago, I hadn’t yet dabbled in the world of 3D printers. I’m not sure why it took so long, but I finally took the leap and spent a few weeks playing with one of the first mass-market 3D printers, 3D Systems’ Cube, a device that’s now available on store shelves at retailers like Staples. It’s easy to see 3D Systems is laser focused on the home and small business market with this device — the printer itself is designed to look like a colorful small kitchen appliance (in other words both chic and non-threatening), it’s compact, relatively easy to use and carries a $1,299 price tag. After two weeks, I believe that 3D printing is an interesting technology, but it’s still largely at the hobbyist level. The combination of cost and limitations in the technology mean 3D printing isn’t ready for prime time — yet.

There’s a lot to like about the Cube. It’s an attractive device and 3D Systems has designed it so that much of the mechanics are hidden. Connectivity can be via Wi-Fi to minimize cables. That simplicity and concealment approach extends to the cartridges the 3D printer uses. They’re sealed units to make things as easy as possible for users – loading the machine up is pretty similar to loading an inkjet printer. But, like an inkjet printer, the Cube is obviously intended to generate ongoing revenue through sales of raw materials. A single cartridge is $49 (the company does offer bulk discounts), and the cartridge is a sealed unit with a chip — I suspect a determined user could crack it open and replace the filament with third party stuff, but doing so would be a pain.

I discovered an immediate drawback to this approach (besides the cost) when I cracked open the review unit. Someone had tucked a nearly full PLA cartridge in the box without securing the filament that extends out of the plastic shell with the result that the filament retracted fully inside the sealed cartridge with no way to extend it back out. I could have cracked it open at that point, but it was a review unit and I had three unopened cartridges to play with. If a Cube owner made the same mistake, that cartridge would likely have been a $50 lesson.

Having never used a 3D printer before, or even personally seen a consumer-level model in action, there were some realities that caught me off guard. GeekDad contributors and readers who are into 3D printing will know all about this stuff and either shrug it off, or point out other manufacturers such as MakerBot as an alternative. As I said, I’m a neophyte when it comes to this area, but I am technically inclined and follow the industry from a distance; if some of these issues surprised me, you can bet they’re going to throw the general public.

Setup

Of course it makes sense that you’d need a stable platform to securely hold the model being printed, but I didn’t realize that means applying glue to the print platform. Yeah, makes sense, but that’s a pain. Alignment of the print head and platform (in three dimensions) is also critical to success, but 3D Systems makes it pretty easy on the Cube and it needed only minor adjustments after shipping.

Cost

Of course any new technology is going to be expensive. I don’t have a problem paying for something that solves a problem or offers a real advantage (in the old days I recall paying $800 or so for an external 2X CD burner). Still, $1,299 is on the high side for a consumer level peripheral (although I noticed Amazon has the Cube for $200 under the MSRP) and the cost of materials is an ongoing and not immaterial expense. I figured I was getting around a half dozen fist-sized objects from a single $50 cartridge, so if you print a lot this could quickly turn into an expensive hobby. And yes, I realize MakerBot went with spools of plastic instead of proprietary cartridges to minimize the expense of consumables, but a Replicator 2 goes for $2,199 which may be reasonable for hobbyists but is really pushing it for consumers.

Realities and/or Limitations

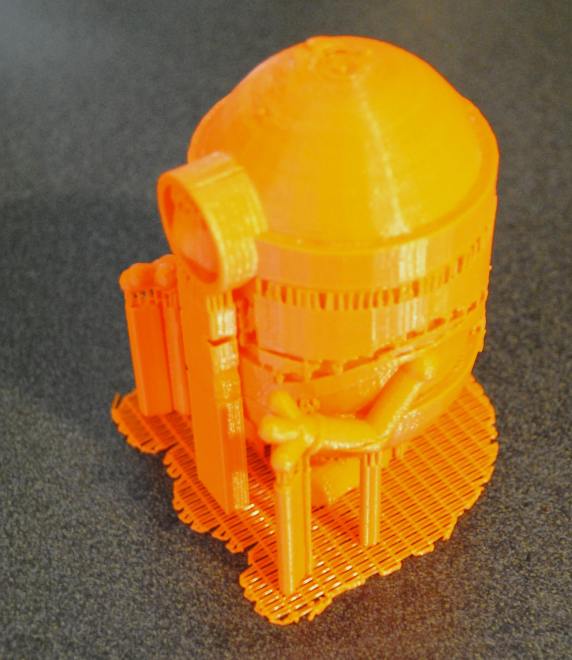

Most of the photos of 3D printed objects you’ll find online (and in promotional material) are of clean, finished objects. They look professional. The output from a 3D printer — at least this 3D printer — is full of support structures that need to be snapped or cut off and sanded smooth before the object comes anywhere close to those photos. And this should be obvious but often gets lost in the hype — large or complex objects (such as those with moving parts) don’t just work that way. You have to print pieces and assemble them. Entry level printers like the Cube are limited to a single color of plastic. Sure you can switch them up for different models, but for multicolored models you need to move to a more expensive printer. Despite online resources like Thingverse, it can be hard to find objects to print, especially if you’re looking for a specific object. With copyright lawyers taking notice of 3D plans posted online, this has the potential to get even trickier before it gets better.

So Slow…

My single biggest complaint was the speed of 3D printing. Yes, the Cube is an entry level printer, so maybe others go faster, but I grew up in a slower world and I’m frustrated by the speed — manufacturers are going to have a hell of a time selling these things to younger buyers in that prime, compulsive technology buying demographic. The same buyers who have grown up in a digital world where everything is available on demand. The simplest model I printed took two hours, the most complex took eight. When I’d invite people over to show them the 3D printer in action, instead of the “Wow!” moment something like this should be, there were a few seconds of curiosity watching the print head zip around doing it’s thing, followed by a glazed eye look when I explained that if we came back in an hour or two, we’d be able to see some progress on the model. That delay lost them.

I learned the only thing more frustrating than waiting eight hours for a model to complete printing (and then have to cut off all the extra bits and finish it), was having a print head jam six hours into an eight hour print job and having to start from scratch. That’s six hours wasted, plus five bucks or more of plastic filament down the drain.

Conclusion

I see the potential of 3D printing. I understand the reason for the interest in our GeekDad community. For those on the bleeding edge, the Cube seems like a reasonable entry point to me, and I think 3D Systems’ approach of making their printer look like an appliance was the right way to approach the consumer market. I think 3D printing is cool and fully expect to buy a 3D printer. But it won’t be for a few more years. Bring the cost down a bit, turn the all-day print jobs into a few hours, make the raw materials a little more reasonable in cost, build up the community of printable designs and 3D printers could have the potential to take off the way inkjet printers did in the home.

The technology is still in primary phase with high expectation in future. 3D printers are already available on the market but the list with objects that can be built with these is still very low. Find many more 3d printers on http://www.intorobotics.com/3d-printers-for-sale-custom-robots/

I really don’t care about the availability of models to print. I want one of these to print things that I design myself. The Cubify Invent software allows just about anyone to create their own objects and it’s very cheap compared to professional CAD software (Blender works too, and that’s free, but much harder to learn).

I have being thinking to get one and the Cube has catch my interest because of how it looks (I don’t want something that looks like it belongs to a factory instead of my desk)… but at this point is like the inkjet printers on the early 2000’s where you use to print one or two color pages only because the cartridge cost was on the $50 or more, maybe to the end of 2015!

the cube 3 is probably faster due to hardware and firmware upgrades. also each cartridge of filament comes with a new extruder attached. This allows the printer to consistently print without errors and last much longer.

Also, the price of the printer has come down.